NEWS / BLOG

Sed interdum massa lacus, a porttitor risus gravida sed. Nulla ultricies ex non sagittis vulputate. Integer fringilla convallis risus, id semper est interdum non.

LATEST ARTICLES

Quisque molestie tristique nisi et luctus. Proin eget velit quis lorem euismod pulvinar. Phasellus lobortis tellus dignissim metus varius volutpat. Integer a lacus mauris.

GAS TURBINE FILTER

The clearcurrent® PG HD filter is designed for both coastal and land-based environments. Available in 4 in. depth, this clearcurrent G4-rated (EN779) filter is designed to suit all types of operating conditions. The clearcurrent PG HD filter is designed for low pressure loss to enable optimum power output. Its high dust-holding capacity ensures an extended high-efficiency filter life, resulting in lower operating costs. To ensure filtration and pressure loss characteristics remain enhanced when operating in wet or dry conditions, the pre-filter utilizes a combination of advanced synthetic media, fully potted and housed in a robust and extremely durable acrylonitrile butadiene styrene plastic frame. Lightweight construction allows easy change-out and low maintenance costs. Download Catalog Here

AIR OIL COOLER

The Parker LAC air oil cooler series offers a reliable and efficient cooling system with the additional benefits of short lead times and 48 delivery for some part numbers. With its simple and robust design and wide selection of accessories this range will suit all industrial applications with a high voltage electric source. The Parker LAC air oil cooler is quiet in operation and offers a low pressure drop and high cooling capacity. It has a single-phase or three-phase AC-motor and is also available in two special versions: • With ATEX approval for use in potentially explosive atmospheres above ground (LAC-X series) • With extra corrosion protection, for use in marine/offshore applications (MAC series) The LAC size 200, which is unique on the market offers a cooling capacity of 300 kW at an estimated temperature difference of 40°C. Technical Specifications : Motor Pole Count : 2,4 Pressure Relief Setting : None, By-Pass 5 bar Maximum Flow Rate : 185, 225, 260, 275, 350, 300, 400, 1000 L/min, 185, 225, 260, 275, 350, 400 L/min Maximum Cooling Capacity : 4,4kW at delta T [...]

CYLINDER

Parker is the world's largest supplier of hydraulic cylinders and parts for industrial applications. Parker manufactures a diverse range of standard and special tie rod, roundline and 'mill' type cylinders to suit all types of industrial cylinder applications. Our cylinders meet every major industry standard, with other certifications available upon request. All Parker hydraulic cylinders and parts are designed to deliver long, efficient service with low maintenance requirements, guaranteeing high productivity throughout the life of the product. Standard Specifications • Heavy Duty Service – ANSI/(NFPA) T3.6.7R3 - 2009 Specifications and Mounting Dimension Standards • Standard Construction – Square Head – Tie Rod Design • Nominal Pressure – 3000 psi1 • Standard Fluid – Hydraulic Oil • Standard Temperature – -10°F to +165°F2 • Bore Diameters – 1.50" through 6.00" (Larger sizes available) [...]

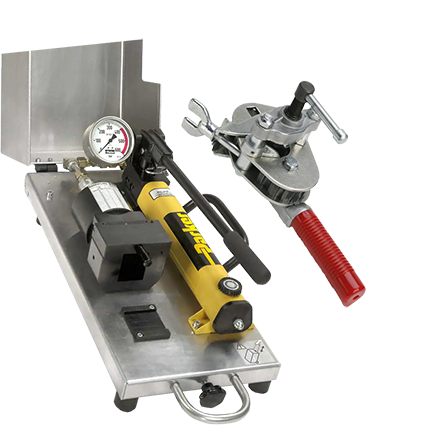

TUBE FLARING / DEBURRING TOOL

The EO-KARRYMAT is a dependable device for safe and efficient bite-type presetting. It allows pre-assembly of even large dimension steel and stainless steel tube at assembly sites where EOMAT technology is not available. The EO-KARRYMAT consists of a hydraulic drive and a handpump. The hydraulic assembly pressure can be read on a gauge. The EO-KARRYMAT comes as one unit with all components firmly attached to a practical carrying frame. Parker's 45° flaring tools with easy to turn handles flares and burnishes soft metal tubing from 3/16" to 3/4" and 5mm to 16mm O.D. tubing. Parker also offers a tool for double flaring. Download Catalog Here

TUBE WITH FITTING

The tube programme from Parker Hannifin gives all possibilities for usage in hydraulic applications. Tubes for fitting- and flange-systems, tubes for mobile and stationary systems. Different dimensions, carbon- and stainless-steel tubes as well as different surfaces are available. Parker tubes are designed for the special requirements in several markets. Continuous tests in laboratories and on test benches ensure the high quality level of the material. Certifications from independent institutes such as ABS, LR or DNV confirm the adherence to high standards. This opens into reliability and longevity of the hydraulic application. The Parker Hannifin tube-warehouse with its worldwide network provides a close and prompt supply of high precision tubes; thus, international customers can also rely on us. Efficient, reliable, environmentally friendly and on-time deliveries are available in almost every country in the world. Ermeto hydraulic DIN fitting components for high pressure hydraulic tube fittings are indispensable items in order to build up a complete fitting series (EO-PSR, EO-2, EO2-FORM). The FM EO-2 functional nut is available with sealing NBR or sealing FKM. Download Catalog Here

PARKRIMP 2

The Parkrimp 2 is Parker's largest and most versatile bench mounted crimper that comes in either single phase or three phase electric. Parker's Parkrimp 2 models can crimp straight or bent-stem steel and stainless steel fittings from ¼” to 2" in diameter including 16, 26, 43, 46, 48, 70, 73 and 77 series. Features/Benefits: • Portable, compact, rugged design • Parker's exclusive Parkalign system, which positions the fitting in the die for a perfect crimp every time • An efficient bottom-loading design that makes it easier for operators to manage long hose assemblies • Linked dies that prevent segments from being misplaced or mismatched • Dies that are color coded by size for easy identification and reduced set-up time • Durability that provides years of reliable service • An information-rich decal that details the list of proper hose and fitting combinations, tools required and the crimp specification for each hose and fitting combination Applications: • Enables any user to make factory-quality hose assemblies Download Catalog Here

QUALITY GUARANTEE

Sed venenatis urna sit amet vulputate lobortis. Nullam dolor sem, varius eu luctus vitae, mattis id dolor. Proin ultricies feugiat ipsum. Quisque lobortis risus sapien, quis pulvinar turpis placerat ut. Vivamus eu egestas est, commodo ultricies turpis. Donec a consequat nisi, non pellentesque risus. Fusce lacinia sem a mollis tempus. Etiam in sapien non odio ornare iaculis vel vel enim. Sed velit urna, pharetra non quam nec, consequat hendrerit ex. Phasellus ac rutrum diam.

FREE QUOTE

Do you need help with hydraulic maintenance? Fill out this form to get in touch.

OFFICE LINE

1.800.555.6789

EMERGENCY

1.800.555.0000

WORKING HOURS

9:00am – 6:00pm

OFFICE LINE

1.800.555.6789

EMERGENCY

1.800.555.0000

WORKING HOURS