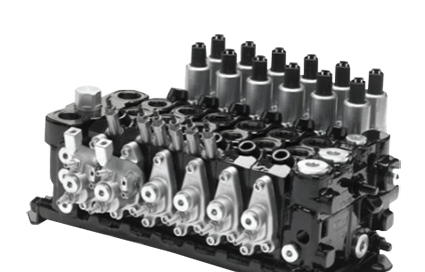

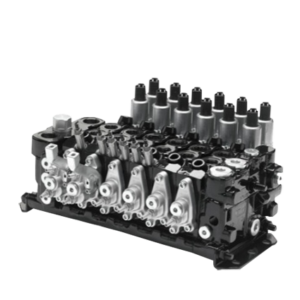

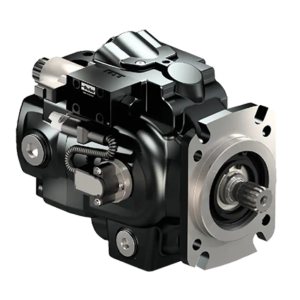

L90LS has a wide range of selectable functions, offering great flexibility in terms of system structure in simple as well as advanced hydraulic system solutions. L90LS is a result of Parker’s wide experience in mobile hydraulics, offering excellent performance, made with high grade materials and precision manufacturing. L90LS can be equipped with manual, hydraulic or electrohydraulic spool actuators in any combination. Each valve section can be optimized for its particular function in the machinery, with a large range of main spools, pressure relief valves, pressure compensators, signal pressure limiters and other performance enhancing functions.

The L90LS hydraulic valve can be constructed in many different designs, with different inlet sections, work sections, end sections and also generic function manifolds for example to obtain proportional pressure control. The L90LS can also be combined with the bigger K220LS directional control valve in order to further optimize functional performance in machinery with large variations in flow requirement.

For complete customer-specific functional adaptation and to accommodate every conceivable need in terms of auxiliary function control, the L90LS can be combined with tailor-made function manifolds, consisting of components from Parker's many product divisions.

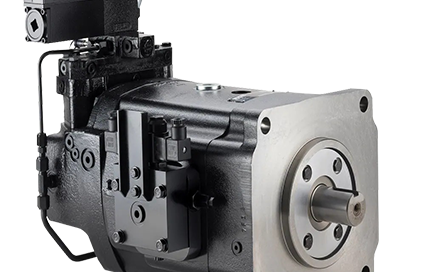

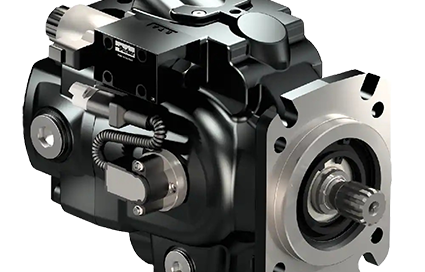

The L90LS is designed to operate in perfect harmony together with Parker pumps, motors, electronic systems and joysticks as well as with equipment from other manufacturers.

- Maximum Operating Pressure : 4786 psi, 330 bar

- Maximum Operating Temperature : +90 °C

- Maximum Flow Rate : 125 L/min

- Minimum Operating Temperature : +20 °C

- Function : Normally closed, 4-way

- Product Type : Mobile Directional Control Valve

- Seal Material : HNBR, NBR

- Valve Type : Sectional

- Valve Configuration : Load Sensing

- For Fluid Type : Hydraulic fluids

- ATEX Specifications Met : Not available

- Operation Type : Manual Control, Hydraulic Control, Pneumatic Control, Electro-hydraulic Control

- Connection Type : BSP, UNF

- Application : Cranes, Skylifts, Forklift Trucks, Platform Trucks, Excavators, Harvesters, Forwarders, Multi-Purpose

Download Catalog Here