Vane pump is a fascinating and highly effective type of positive displacement pump that play a significant role in improving industrial efficiency across various sectors. Their unique design allows them to deliver a consistent and reliable flow, even under varying pressure conditions, which translates into numerous benefits for industrial operations.

How a Vane Pump Works

Before we delve into the efficiency improvements, it’s helpful to briefly understand the core mechanism. A vane pump consists of a rotor that is eccentrically mounted within a cylindrical housing. This rotor has radial slots that hold vanes (blades) that are free to slide in and out. As the rotor turns, centrifugal force and/or springs push these vanes against the inner surface of the housing.

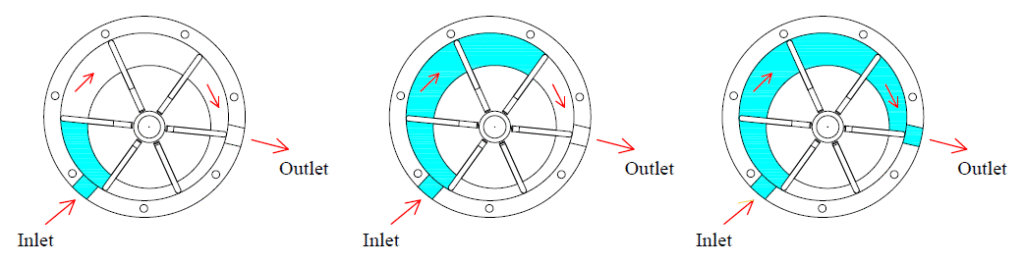

Here’s a simplified breakdown of the pumping action:

Fluid Intake – As the rotor turns, the space between the vanes and the housing increases, creating a vacuum that draws fluid into the pump’s inlet.

Fluid Transport – The fluid is then trapped between the vanes and carried around the housing as the rotor continues to rotate.

Fluid Discharge – As the space between the vanes and the housing decreases, the fluid is compressed and forced out through the pump’s outlet.

Key Ways Vane Pumps Enhance Industrial Efficiency

High Volumetric Efficiency

Consistent Flow – Vane pumps are known for their high volumetric efficiency, meaning they deliver a very consistent and predictable flow rate per revolution. This is crucial for applications requiring precise fluid metering or steady delivery, reducing waste and ensuring product quality.

Minimal Slip – The vanes maintain close contact with the housing, minimizing internal leakage (slip) of the fluid from the discharge back to the inlet. This ensures that most of the fluid drawn into the pump is actually delivered, reducing energy wasted on recirculating fluid.

Energy Efficiency

Self-Compensating Vanes – Many vane pumps feature self-compensating vanes that adjust their position against the housing as wear occurs.

Variable Displacement Options – Some vane pumps offer variable displacement capabilities.

Lower Noise and Vibration – The smooth, continuous pumping action of vane pumps generally results in lower noise and vibration levels compared to some other pump types.

Reliability and Durability

Tolerance to Contaminants – Vane pumps are moderately sensitive to fluid contamination compared to other hydraulic pump types. Their internal design relies on close clearances and smooth vane movement inside the rotor slots, making them less tolerant of solid particles or poor-quality fluids.

|

Pump Type |

Contaminant Tolerance |

Typical Cleanliness Requirement (ISO 4406) |

| Gear Pump | High (most tolerant) | 20/18/15 or cleaner |

| Vane Pump | Moderate | 18/16/13 or cleaner |

| Piston Pump | Low (most sensitive) | 16/14/11 or cleaner |

Long Service Life – To maximize lifetime (typically 10,000 – 20,000 operating hours or more under proper conditions)

| Condition | Recommendation | Reason |

| Fluid Cleanliness | Maintain ISO 18/16/13 or cleaner | Prevents scoring and vane sticking |

| Fluid Type | Use high-quality hydraulic oil (anti-wear, good lubricity) | Ensures smooth vane movement |

| Operating Pressure | Operate within rated pressure (typically 100–210 bar) | Prevents vane tip and cam ring damage |

| Viscosity Range | 25–75 cSt (start-up), 16–36 cSt (operating) | Ensures proper lubrication film |

| Temperature Control | Keep oil below 60°C continuous | Avoids oxidation and viscosity loss |

| Proper Filtration | 10 μm absolute filter on return line | Removes damaging particles |

Easy Maintenance – Vane pumps are widely used in hydraulic and lubrication systems because they offer reliable performance with simple and low-cost maintenance. Their modular design and few moving parts make servicing quick and straightforward.

| Feature | Description | Maintenance Benefit |

| Few moving parts | Mainly rotor, vanes, cam ring, and side plates | Easier to inspect and reassemble |

| Cartridge design (in many models) | Pumping section can be removed as a cartridge | Enables quick replacement without disconnecting lines |

| Self-compensating vanes | Vanes automatically adjust to wear | Reduces need for frequent adjustments |

| Replaceable wear plates | Protects housing from wear | Only wear components are replaced, not the entire housing |

| Symmetrical design | Can rotate both directions (in some types) | Simplifies installation and service |

Versatility Across Applications

Wide Range of Fluids – Vane pumps are suitable for a broad spectrum of fluids, from thin solvents to viscous oils, and even some non-lubricating fluids (with appropriate material selection).

Compact Design – Their relatively compact design can save valuable floor space in industrial facilities.

Vane Pump Applications and Their Efficiency Benefits

Hydraulic Systems: In industrial machinery (e.g., presses, forklifts, construction equipment), variable displacement vane pumps are crucial. They provide on-demand flow, reducing energy consumption by only providing hydraulic power when needed, unlike fixed-displacement pumps that continuously run at full capacity.

Fuel Transfer and Dispensing: Vane pumps are widely used in fuel stations and bulk fuel transfer. Their consistent flow and ability to handle various fuel types ensure efficient and accurate delivery, minimizing spills and waste.

Lubrication Systems: In engines and industrial equipment, vane pumps deliver precise amounts of lubricating oil, ensuring optimal performance and extending the life of components by preventing friction and wear. This directly reduces maintenance costs and downtime.

Chemical Processing: With appropriate material selection (e.g., stainless steel, specialized elastomers), vane pumps are used to transfer a variety of chemicals, offering precise metering and reliable flow in sensitive processes

Besttoflow Specialty : Parker for Industrial and Mobile Vane Pump

At 2004, Parker Hannifin Corporation acquired Denison Hydraulics, one of the most recognized global brand for vane pump. After the acquisition, Parker gradually rebranded Denison’s hydraulic products under the Parker name, though the “Denison” label is still often used informally to refer to certain product lines — particularly the T6, T67, and T7 vane pump series, now marketed as Parker Denison.

These vane pumps design is specially for high/low circuits. The combination of different cartridges in double and triple pumps allows low flow at high pressure (300 bar max.) and high flow at lower pressure. This is a clever way to optimize your circuit design. This pump feature will also allow a very fast pressure cycle change with a very precise flow repeatability.

T6, T67 AND T7 are available in 5 sizes:

| SIZE | DISPLACEMENT | PRESSURE |

| A | 5,8 to 40,0 ml/rev | up to 300 bar max. |

| B | 5,8 to 50,0 ml/rev | up to 320 bar max. |

| C | 10,8 to 100,0 ml/rev | up to 275 bar max. |

| D | 44,0 to 158,0 ml/rev | up to 280 bar max. |

| E | 132,3 to 268,7 ml/rev | up to 240 bar max. |

The pumps has mounting flexibility to be assembled as single pump, double pump and triple pump with up to 128 different positions.

Find more information about our vane pump here.