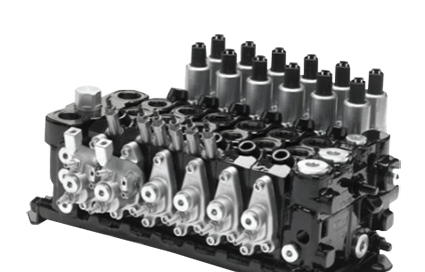

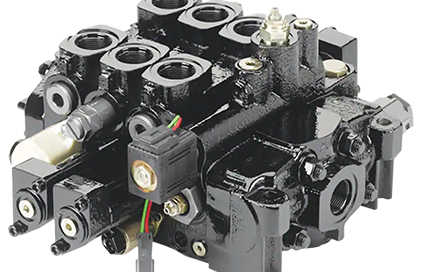

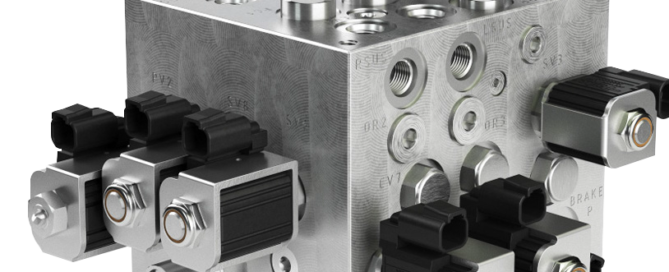

SOLENOID VALVE

Parker’s D1VW directional control valves are high performance on/off direct operated hydraulic valves. There are 15 solenoid voltage options including DC, DC rectified and true AC voltages. There are 9 basic termination options including DIN, Deutsch, conduit box with wires and conduit box with plug-in coils. The conduit box with plug-in coils also allows for connections including terminal strip, Manaplug (Brad Harrison) and micro connection (M12 connector). D1VW valves are available with other options such as soft shift tubes (4 orifice size options), monitor switches, extended manual over rides and surge suppression diodes. DIN connector and Conduit box connections provide an IP65 (NEMA 4) ingress rating

The D1VW valve is well suited for both the industrial and mobile applications. Painted bodies and Deutsch connectors are offered for tough environment applications.

Technical Specifications

- Function:001 - 4-way, 3 position; All Ports Blocked

- Configuration:C - Double solenoid, 3 position, spring centered

- Input Voltage:120 VDC

- Seal Material:Buna

- Division:Hydraulic Valve

- Body Material:Ductile Iron

- Actuation Type:Solenoid

- For Fluid Type:Hydraulilc Oil

- Mounting Type:Subplate

- Maximum Flow Rate:22 GPM (Depending on Spool)

- Function:001 - 4-way, 3 position; All Ports Blocked

- Configuration:C - Double solenoid, 3 position, spring centered

- Seal Material:Buna

- Input Voltage:120 VDC

- Coil Type:DIN w/Plug

- Solenoid Option:N/A

- Electrical Part Option:N/A

- Orifice Size:N/A

- Coil Specifications Met:N/A

- Additional Options:N/A

- Maximum Operating Pressure:5000 psi

- Maximum Operating Temperature:60 °C

- Minimum Operating Temperature:-25 °C

- Weight:4.5 lb

Download Catalogue Here