FOOD HOSE

Parker's PURE food grade hoses enable a clean and safe transfer of a wide variety of foods, beverages and sanitary materials. Our products are offered in a comprehensive range of constructions and also offer multiple colors, pressures, sizes and temperature capabilities to meet customer needs. All of our food grade hoses meet government and industry standards and our hose tubes are suitable for a variety of markets. They also offer full suction capability and kink resistance to extend their usability and enhanced cover options for convenient cleaning. Explore our markets below and learn more about Parker PURE hoses.

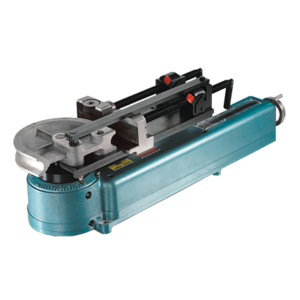

Premium quality, extra flexible delivery and suction hose designed for both fatty and non-fatty food products.

- 150 psi working pressure

- -13°F / +176°F ( -25°C / +80°C)

- Tube : White Nitrile, phthalates free

- Reinforcement : Synthetic plies, galvanized wire helices

- Sizes : 1", 1-1/2", 2", and 3"

Download Catalog Here